Solder Flux Market Poised to Reach USD 452.7 Million by 2035, Driven by Electronics Innovation and Automotive Growth

UK solder flux market to grow 5.7%, driven by telecom & automation demand. Eco-friendly, water-soluble & hybrid fluxes lead sustainable PCB production.

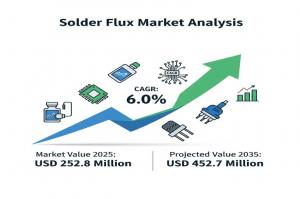

NEWARK, DE, UNITED STATES, August 26, 2025 /EINPresswire.com/ -- The global Solder Flux Market is entering an exciting decade of growth and transformation. Valued at USD 252.8 million in 2025, the market is projected to reach USD 452.7 million by 2035, expanding at a steady CAGR of 6.0%. This upward trajectory is underpinned by the relentless expansion of electronics manufacturing, rising demand for automotive electronics, and the acceleration of sustainable, compliance-driven innovations in soldering materials.

Between 2025 and 2030, the market is expected to grow from USD 252.8 million to USD 338.3 million, with year-on-year increases powered by miniaturization trends, high-speed electronic components, and surface-mount technology (SMT). By 2026, the market will reach USD 268.0 million, progressing to USD 284.1 million in 2027, USD 301.1 million in 2028, USD 319.2 million in 2029, and USD 338.3 million by 2030.

This consistent growth reinforces solder flux’s role as a critical enabler in electronics production, ensuring defect-free solder joints and strong electrical connectivity in the most complex devices.

Rising Demand for High-Performance Flux Formulations

The shift toward lead-free and halogen-free fluxes in compliance with RoHS directives is reshaping the competitive landscape. Manufacturers are investing heavily in low-residue and water-soluble formulations that not only enhance quality but also streamline manufacturing efficiency.

As electronics become smaller, lighter, and more powerful, flux formulations must deliver precise wetting, minimal residue, and strong reliability. These performance expectations are driving innovation in flux chemistry and automated application methods, giving both established companies and new entrants opportunities to differentiate their portfolios.

Key Market Takeaways

• Market Value (2025): USD 252.8 million

• Forecast Value (2035): USD 452.7 million

• CAGR (2025–2035): 6.0%

• Leading Product Segment (2025): No-clean flux (46.3%)

• Leading Sector (2025): Consumer electronics (52.7%)

• Top Regions: North America, Asia-Pacific, Europe

• Top Companies: Henkel, PREMIER INDUSTRIES, MacDermid Alpha Electronics Solutions, Indium Corporation, INVENTEC PERFORMANCE CHEMICALS, KOKI Company Ltd., La-Co Industries Inc., Shenzhen Tong Fang Electronic New Material Co., Ltd., FCT Solder, Johnson Matthey

Growth Drivers and Trends

1. Miniaturization and Higher Component Density: Advanced packaging and SMT processes demand fluxes that can maintain strong joint integrity under tight tolerances. Vendors offering validated water-soluble, no-clean, and rosin-based products are set to win preference in high-volume electronics manufacturing.

2. Environmentally Compliant Solutions: Strict regulations in Europe and North America are accelerating the adoption of VOC-free, lead-free, and halogen-free flux formulations. Manufacturers that innovate in this space will gain competitive advantages.

3. Regional Expansion in Asia-Pacific and Latin America: Fast-growing electronics hubs in China, India, and Southeast Asia are fueling demand for customized flux solutions. Localized manufacturing and supply chain presence will be essential for capturing these opportunities.

4. Technology Integration: Automated soldering processes, selective soldering systems, and smart monitoring solutions are boosting adoption of flux products compatible with next-generation electronics production lines.

Segmental Insights

• By Product:

No-clean flux dominates with 46.3% of revenues in 2025, thanks to its efficiency, reduced cleaning requirements, and compliance with sustainability goals.

• By Sector:

Consumer electronics leads with 52.7% share in 2025, reflecting the industry’s insatiable appetite for compact, reliable, and high-performance devices such as smartphones, wearables, and IoT gadgets.

• By Geography:

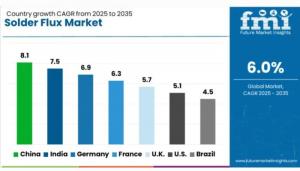

o China: Fastest growth at 8.1% CAGR, fueled by 5G, IoT, and high-volume PCB production.

o India: Expanding at 7.5% CAGR, driven by Make-in-India initiatives and automotive electronics.

o Germany: Growth at 6.9% CAGR, emphasizing precision soldering for automotive and renewable energy.

o France & UK: Focus on eco-friendly, low-residue, and hybrid fluxes to support aerospace, telecom, and industrial automation sectors.

Competitive Landscape

The solder flux market is moderately consolidated, with Henkel leading due to its broad portfolio of advanced flux formulations. Other major players, including MacDermid Alpha Electronics Solutions, Indium Corporation, PREMIER INDUSTRIES, INVENTEC PERFORMANCE CHEMICALS, KOKI Company Ltd., La-Co Industries Inc., Shenzhen Tong Fang Electronic New Material Co., Ltd., FCT Solder, and Johnson Matthey, are actively strengthening their portfolios.

• Established leaders are doubling down on R&D investments, eco-friendly innovations, and global distribution networks.

• New entrants and regional players are focusing on customized, application-specific solutions to cater to fast-growing emerging markets.

This balance creates a dynamic environment where large global firms set the pace, but nimble innovators can capture niche opportunities.

Request Organophosphate Solder Flux Market Draft Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-23015

For more on their methodology and market coverage, visit https://www.futuremarketinsights.com/about-us.

Opportunities Ahead: For Both Established and New Manufacturers

The next decade will be marked by rapid changes in electronics, automotive, aerospace, and renewable energy sectors, creating enormous opportunities for solder flux suppliers.

• For established manufacturers like Henkel and Indium Corporation, scaling eco-friendly product lines and integrating advanced fluxes into automated soldering systems will be key growth drivers.

• For new entrants and mid-sized companies, there is room to innovate with cost-effective, localized, and compliance-friendly formulations tailored to regional needs. Markets in Asia-Pacific, Latin America, and Eastern Europe are particularly ripe for expansion.

By aligning strategies with sustainability, compliance, and high-performance electronics demand, manufacturers can secure long-term competitive advantage in the solder flux industry.

Related Insights from Future Market Insights (FMI)

Non-Corrosive Fluxes Market - https://www.futuremarketinsights.com/reports/non-corrosive-fluxes-market

Copper Tube Market - https://www.futuremarketinsights.com/reports/copper-tube-market

Isotearic Acid Market - https://www.futuremarketinsights.com/reports/isotearic-acid-market

Editor’s Note:

The solder flux market is entering a transformative decade, fueled by advancements in electronics manufacturing and sustainable soldering solutions. With rising demand from telecommunications, automotive, and industrial automation, flux innovations are shaping the future of high-reliability circuits. This report offers valuable insights for manufacturers seeking growth and competitive advantage.

Rahul Singh

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.